Instant Adhesives CEMEDINE 3000 Series

Instant Adhesives

Mainly composed of alkyl-alpha-cyanoacrylate, instantaneous adhesive is polymerized and cured by a small amount of moisture absorbed on the surface of the adherend in a very short time (in several seconds).

Features

- Quick curing

The instantaneous adhesive features the highest curing speed of all adhesives; curing is achieved in several seconds at a normal temperature. - Excellent adhesion

The instantaneous adhesive adheres to a great variety of adherends, providing adhesion as powerful as that of epoxy adhesive. - Simple adhesion

It is a one-part adhesive which does not require the use of a hardener or catalyst. Furthermore, adhesion is completed by one drop of coating and gentle fixation. - Solventless adhesive

The instantaneous adhesive exhibits little curing shrinkage. It does not involve contamination of the work site environment due to organic solvent, as in the case of a rubber adhesive.

Application

- Adhesion of rubber parts

- Adhesion of electric, electronic, precision and automotive parts

- Adhesion of arts and crafts, personal ornaments, jewelry, toys, fishing tackle and sports goods

- Prevention of screws and bolts from getting loose

- Repair of cracks on natural stone

- Adhesion of porous materials (jelly, woodworking)

Product details

・Super-quick curing type : 3000RX series

・Shock resistance type : 3000DX series

・Standard type : 3000Super/3000Gel series

Product data

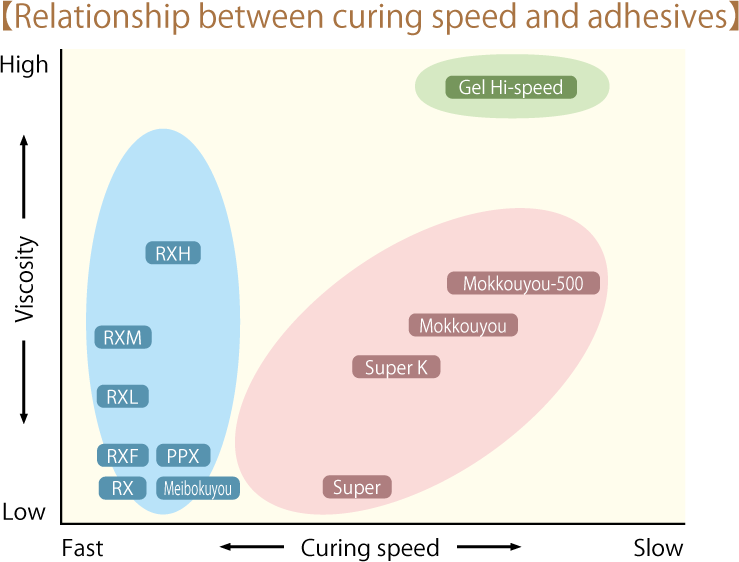

Curing speed and viscosity

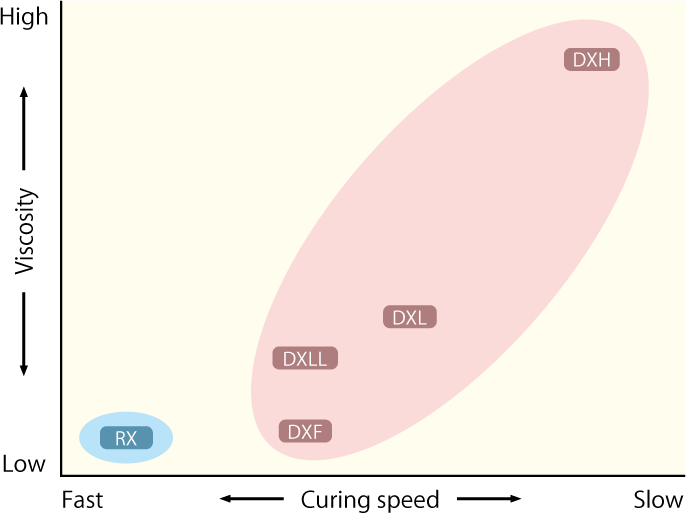

Curing speed and viscosity (3000DX Series)

Super-quick curing type : 3000RX series

Set time and adhesion (3000RX series)

| Adherends | 3000RX | 3000RXF | 3000RXL | 3000RXM | 3000RXH | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Set time | (MPa) | Set time | (MPa) | Set time | (MPa) | Set time | (MPa) | Set time | (MPa) | |

| Steel | 5 sec | 13.0 | 5 sec | 13.0 | 5 sec | 13.0 | 5 sec | 14.0 | 15 sec | 14.0 |

| Aluminum | 3 sec | 11.0 | 3 sec | 11.0 | 5 sec | 11.0 | 5 sec | 11.0 | 15 sec | 12.0 |

| Copper | 3 sec | 10.0 | 3 sec | 10.0 | 5 sec | 10.0 | 5 sec | 10.0 | 15 sec | 11.0 |

| Chromium plated steel | 3 sec | 10.0 | 3 sec | 10.0 | 5 sec | 10.0 | 5 sec | 10.0 | 15 sec | 11.0 |

| ABsec | 2 sec | 5.0* | 2 sec | 5.0* | 2 sec | 5.0* | 3 sec | 5.0* | 3 sec | 5.0* |

| Acrylic resin | 10 sec | 6.0* | 10 sec | 6.0* | 20 sec | 6.0* | 25 sec | 6.0* | 30 sec | 6.0* |

| Polystyrene | 5 sec | 4.0* | 5 sec | 4.0* | 10 sec | 4.0* | 10 sec | 4.0* | 20 sec | 4.0* |

| Unplasticized polyvinyl chloride | 3 sec | 5.0* | 3 sec | 5.0* | 3 sec | 5.0* | 3 sec | 5.0* | 5 sec | 5.0* |

| Bakelite | 5 sec | 7.0* | 5 sec | 7.0* | 5 sec | 7.0* | 10 sec | 7.0* | 15 sec | 7.0* |

| Nylon | 5 sec | 6.0* | 5 sec | 6.0* | 5 sec | 6.0* | 10 sec | 6.0* | 15 sec | 6.0* |

| Polycarbonate | 5 sec | 10.0* | 5 sec | 10.0* | 5 sec | 10.0* | 10 sec | 10.0* | 15 sec | 10.0* |

| NR | 1 sec | 0.5* | 1 sec | 0.5* | 1 sec | 0.5* | 2 sec | 0.5* | 3 sec | 0.5* |

| CR | 1 sec | 0.7* | 1 sec | 0.7* | 1 sec | 0.7* | 2 sec | 0.7* | 3 sec | 0.7* |

| SBR | 1 sec | 0.6* | 1 sec | 0.6* | 1 sec | 0.6* | 1 sec | 0.6* | 3 sec | 0.6* |

| NBR | 1 sec | 0.7* | 1 sec | 0.7* | 1 sec | 0.7* | 2 sec | 0.7* | 3 sec | 0.7* |

| EPDM | 1 sec | 1.1* | 1 sec | 1.1* | 1 sec | 1.1* | 1 sec | 1.1* | 3 sec | 1.1* |

| TPE | 3 sec | 1.8* | 3 sec | 1.8* | 5 sec | 1.8* | 5 sec | 1.8* | 10 sec | 1.8* |

Asterisk (*) indicates material failure.

Property (3000RX series)

| 3000RX | 3000RXF | 3000RXL | 3000RXM | 3000RXH | |||

|---|---|---|---|---|---|---|---|

| Application / Properties / Features | Super-quick curing adhesion resistant material | ||||||

| Base | Ethyl-2-cyanoacrylate | Ethyl-2-cyanoacrylate | Ethyl-2-cyanoacrylate | Ethyl-2-cyanoacrylate | Ethyl-2-cyanoacrylate | ||

| External appearance | Colorless transparent | Colorless transparent | Colorless transparent | Colorless transparent | Colorless transparent | ||

| Non volatiles | % | 100 | 100 | 100 | 100 | 100 | |

| Flash point | °C | 75 | 75 | 75 | 75 | 75 | |

| Viscosity | mPa・s/23°C | 3 | 15 | 100 | 300 | 1000 | |

| Specific gravity | g/cm3 | 1.21~1.25 | 1.21~1.25 | 1.21~1.25 | 1.21~1.25 | 1.21~1.25 | |

| Set time | 23°C | 5 sec | 5 sec | 5 sec | 5 sec | 15 sec | |

| Glass transfer point | °C | 175~182 | 175~182 | 175~182 | 175~182 | 175~182 | |

| linear expansion coefficient | ppm/K | 1.26 | 1.26 | 1.26 | 1.26 | 1.26 | |

| Volume resistivity | Ω・cm/30°C | 8.6x1012 | 8.6x1012 | 8.6x1012 | 8.6x1012 | 8.6x1012 | |

| Insulation breakdown voltage | kv/0.1mm | 14.6 | 14.6 | 14.6 | 14.6 | 14.6 | |

| Dielectric constant | 10Mc, 10℃ | 3.54 | 3.54 | 3.54 | 3.54 | 3.54 | |

| Dielectric loss tangent | 10Mc, 10℃ | 0.068 | 0.068 | 0.068 | 0.068 | 0.068 | |

| Tensile shear strength | MPa | 13 | 13 | 13 | 13 | 13 | |

| Method of applying | Apply right from the container | Apply right from the container | Apply right from the container | Apply right from the container | Apply right from the container | ||

| Capacity | 20g | 20g | 20g | 20g | 50g | ||

| 50g | 50g | 50g | |||||

| Check it at Online-Shop | |||||||

Shock resistance type : 3000DX series

Peel strength (3000DX series)

| Adherends | 3000DXL | 3000DXH |

|---|---|---|

| Steel plate (grinding) | 1.96 | 3.12 |

| Steel plate | 1.16 | 2.76 |

| Aluminum | 3.12 | 3.12 |

| Stainless steel | 1.16 | 3.52 |

| Copper | 0.80 | 1.56 |

| Zinc | 1.56 | 1.96 |

Property (3000DX series)

| 3000DXF | 3000DXLL | 3000DXL | 3000DXH | |||

|---|---|---|---|---|---|---|

| Application / Properties / Features | High-strength, impact-resistant | |||||

| Base | Ethyl-2-cyanoacrylate | Ethyl-2-cyanoacrylate | Ethyl-2-cyanoacrylate | Ethyl-2-cyanoacrylate | ||

| External appearance | Colorless transparent | Colorless transparent ~ Translucent jelly | Colorless transparent ~ Translucent jelly | Colorless transparent ~ Translucent jelly | ||

| Non volatiles | % | 100 | 100 | 100 | 100 | |

| Flash point | °C | 75 | 75 | 75 | 75 | |

| Viscosity | mPa・s/23°C | 10 | 100 | 300 | 3000 | |

| Specific gravity | g/cm3 | 1.05 | 1.05 | 1.05 | 1.05 | |

| Set time | 23°C | 30 sec | 45 sec | 60 sec | 75 sec | |

| Tensile shear strength | MPa | 21 | 21 | 21 | 22 | |

| T-peel strength | N/mm | 2.0 | 2.5 | 3 | ||

| Method of applying | Apply right from the container | Apply right from the container | Apply right from the container | Apply right from the container | ||

| Capacity | 20g | 20g | 20g | 50g | ||

| 50g | ||||||

| Check it at Online-Shop | ||||||

Standard type : 3000Super/3000Gel series

Property (Standard type)

| 3000 Super | 3000 Super K | |||

|---|---|---|---|---|

| Application / Properties / Features | Standard | |||

| Base | α- cyanoacrylate | α- cyanoacrylate | ||

| External appearance | Colorless transparent | Colorless transparent | ||

| Non volatiles | % | 100 | 100 | |

| Viscosity | mPa・s/23°C | 3 | 100 | |

| Specific gravity | g/cm3 | 1.05 | 1.05 | |

| Set time | 23°C | 10 sec | 20 sec | |

| Method of applying | Apply right from the container | Apply right from the container | ||

| Capacity | 20g | 20g | ||

| 50g | 50g | |||

| Check it at Online-Shop | ||||

Property (Gel type)

| 3000 Gel HI-Speed | |||

|---|---|---|---|

| Application / Properties / Features | Gel | ||

| Base | α- cyanoacrylate | ||

| External appearance | Colorless transparent ~ Translucent jelly | ||

| Set time | 23°C | 25 sec | |

| Method of applying | Apply right from the container | ||

| Capacity | 20g | ||

| 50g | |||

| 350g | |||

| Check it at Online-Shop | |||

Check it at Online-Shop

※ The link destination is an external site.

※ The link will be broken due to the circumstances of the link seller.

Description of the mark

-

This mark means that products comply with RoHS Directiverequirements.

-

This mark means that products comply with Japanese formaldehyde emission standards for adhesives. These are set forth by the Japanese Industrial Standards (JIS) or Japan Adhesive Industry Association (JAIA).

-

This mark means that products comply with Japanese Voluntary VOC Regulating Rule for Indoor Air Pollution Control. These are set forth by Japan Adhesive Industry Association (JAIA).

-

This mark is a self-management mark for people and environmentally friendly products. We provide products that address environmental and health concerns, mainly for construction and housing applications.