Elastic adhesive Super X series

Elastic adhesive | Super X

Cemedine Super X is an innovative one-part, quick cure adhesive with three key features: "Pressure-sensitive adhesion", "Elastic adhesion" and "Solvent-free adhesion", which are the ideal properties of adhesives. It is used around the world.

Features

Multi-purpose adhesive for high-performance bonding of numerous materials.

One-part solventless type providing quick curing at room temperature

High durability

Super X as elastic adhesives does not peel off. Once materials are adhered, Super X provides durability in the range from low temperature (-60°C) to high temperature (120°C). Because of the rubber state of the hard film, the Super X sufficiently follows expansion, shrinkage and other changes of adherends.

Siloxane-free

There is not including low molecular weight cyclosiloxane. (D3 to D10 Cyclosiloxane compound)

Application

- For bonding application that requires initial rise strength.

- For bonding applications of dissimilar materials with different coefficients of thermal expansion.

- For bonding applications that require durability, such as thermal cycling.

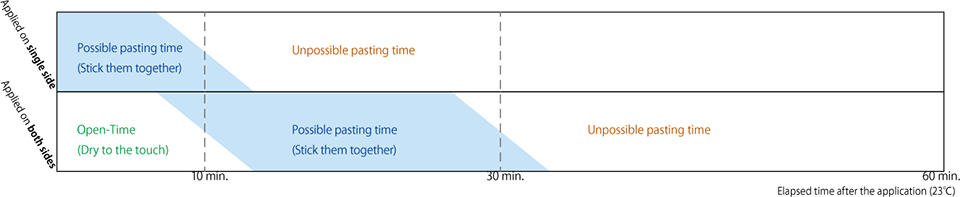

- There are two ways to use: single sided and double sided.

Please use properly depending on the material and the conditions to be attached.

[Method 1: Single-sided application]

- In the case of porous material.

- In the case of the bonding area is small.

[Method 2: Double-sided application (like contact cement)]

- In the case of non-porous materials such as metal, plastic and ceramic.

- When the initial rising adhesion strength is required, such as warped parts, adhesion to vertical surfaces, adhesion of heavy materials, etc.

Initial curing process

Representative test data

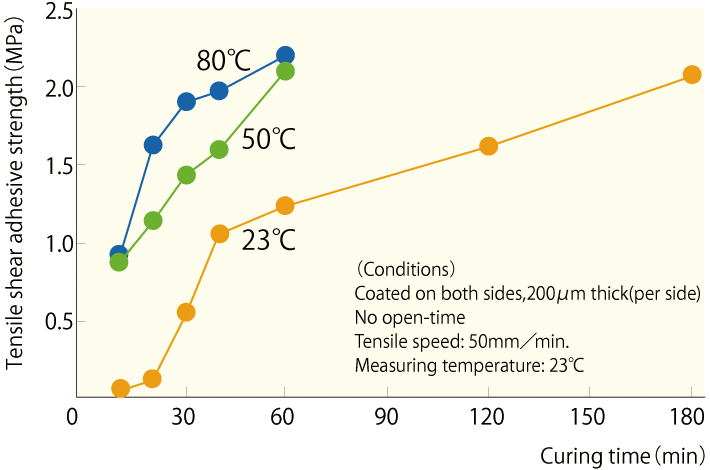

Initial curing speed by environmental temperature

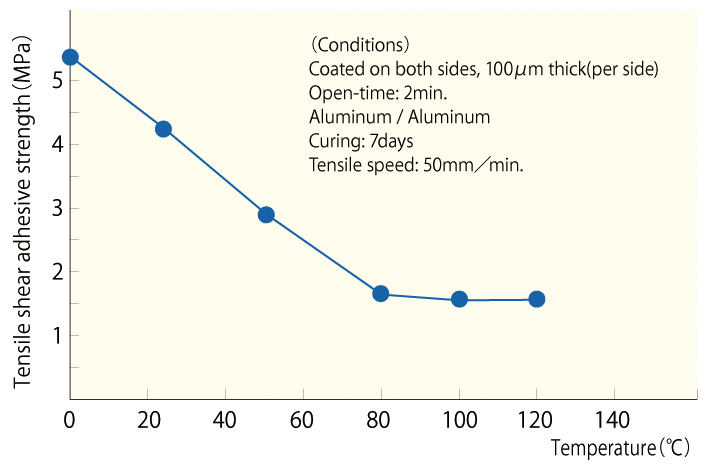

Tensile shear strength on each temperature

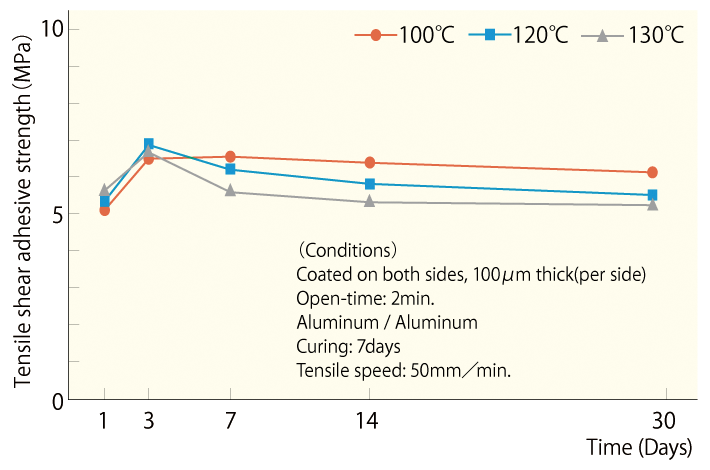

Tensile shear strength after heat aging

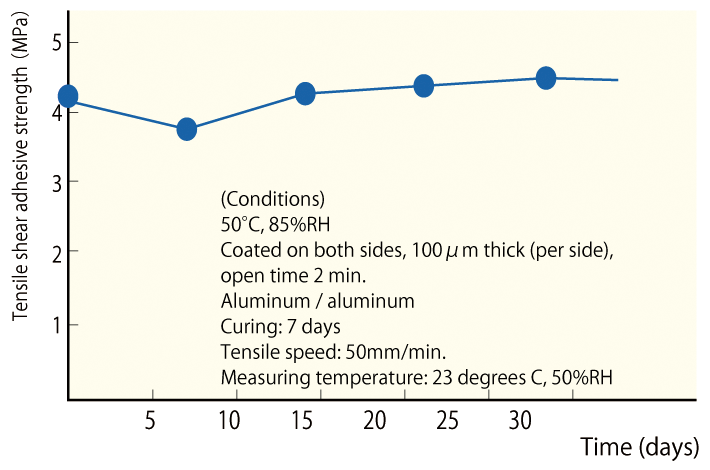

Tensile shear adhesive strength after High-temperature and High-humidity

Adhesive strength for various types of adherends

(MPa)| Adherends | Tensile shear adhesive strength after 7-day curing |

||

|---|---|---|---|

| Metal | Steel plate (SPCC, SPCD) | 3.32 | CF |

| Aluminum(*1) | 4.26 | CF | |

| Stainless steel | 2.24 | AF | |

| Copper | 3.62 | CF | |

| Plastics | Polycarbonate | 3.29 | CF |

| Bakelite | 4.43 | CF | |

| ABS | 3.10 | CF | |

| Unplasticized polyvinyl chloride | 3.08 | CF | |

| Styrene | 2.40 | CF5 AF5 | |

| Acryl | 3.22 | CF | |

| 6-nylon | 3.28 | CF | |

| FRP(*2) | 2.92 | CF | |

| Polypropylene(*3) | 2.77 | CF5 AF5 | |

| PET(Polyethylene terephthalate) | 2.22 | CF3 AF7 | |

| PPS(Polyphenylene sulfide) | 1.60 | AF | |

| PPO(Polyphenylene oxide) | 3.16 | CF | |

| PAR(Polyarylate) | 1.10 | AF | |

| Others | Slate | 1.01 | MF |

| Plywood | 3.60 | CF | |

CF:Cohesion Failure, AF:Adhesive Failure, MF:Failure Modes

Coated on both sides, 50µm thick (one side),tension speed between adherends: 50mm/min

*1 and *2: Surface preparation causes adhesive strength to become uneven; it must be confirmed in advance.

*3: Primer (Cemedine PP-7F) to be used.

Adhesive strength for various types of rubbers

(N/mm)| Adherends | Peeling adhesive strength after 7-day curing |

||

|---|---|---|---|

| Rubbers | NBR | 0.27 | AF |

| Silicone rubber | 0.45 | AF | |

| EPDM | 0.60 | AF | |

| EPDM(*) | 2.73 | CF | |

| CR (Chloroprene rubber) (*) | 0.43 | AF | |

(*)…Degreasing by MEK after treatment by sandpaper (#120)

Chemicals resistance

(MPa)| Chemicals | Tensile shear strength after dipping in chemicals |

|

|---|---|---|

| Initial Value | 2.24 | AF |

| Water | 3.00 | CF5 AF5 |

| Acetic acid (1% water solution) | 2.05 | CF4 AF6 |

| Acetic acid (10% water solution) | 1.22 | CF3 AF7 |

| Sulfuric acid (3% water solution) | 2.93 | CF2 AF8 |

| Sulfuric acid (30% water solution) | 2.05 | AF |

| Sodium hydroxide (1% water solution) | 2.84 | CF5 AF5 |

| Sodium hydroxide (10% water solution) | 3.29 | CF2 AF8 |

| Machine oil (Idemitsu: Mechanic Oil) | 2.96 | CF5 AF5 |

| Salt (10% water solution) | 3.16 | CF4 AF6 |

| MEK* | 0.11 | AF |

| n-Hexane* | 0.56 | AF |

CF:Cohesion Failure, AF:Adhesive Failure

Adherends : Stainless steel x Stainless steel

Surface preparation : Degreasing with MEK

Coating quantity : Coated on both sides 50μm thick (per side)

Open time : 2 min

Pressing : 2 pinches

Curing : 23°C50%RH x 7 days

Chemical immersion : 23°C x 7 days

Tension speed : 50 mm/min

Destruction State : Confirmation by seeing

*… Deterioration of solvent is observed, but no problem with short-time contact, for example, in washing.

Property

| Super X No.8008 | |||||||

|---|---|---|---|---|---|---|---|

| White | Black | L Black | LL Black | Clear | |||

| Type | One component type Elastic Adhesive | ||||||

| Standard type | Low viscosity type | Clear type | |||||

| Base | Special polymer containing silyl group | ||||||

| Appearance | White paste | Black paste | Light yellow clear paste | ||||

| Viscosity | Pa・s/23°C | 85.0 | 85.0 | 22.0 | 19.0 | 82.6 | |

| Specific gravity | g/cm3 | 1.27 | 1.27 | 1.25 | 1.22 | 1.07 | |

| Skin over time | 23°C | 11min | 11min | 11min | 12min | 8.5min | |

| Adhesive property | Tensile shear adhesive strength | MPa | 4.0 | 4.0 | 3.5 | 3.3 | 3.5 |

| T type peeling adhesive strength | N/mm | 2.0 | 2.0 | 2.1 | 1.0 | 3.4 | |

| Curing properties | Hardness | Shore A | 43 | 43 | 35 | 34 | 50 |

| Glass transfer point | °C | -63 | -63 | -68 | -59 | -64 | |

| Breaking strength | MPa | 2.5 | 2.5 | 1.3 | 0.9 | 4.0 | |

| Elongation at break | % | 200 | 200 | 320 | 200 | 170 | |

| Electric Characteristics | Volume resistivity | Ω・cm | 1.1 x 1012 | 4.7 x 1011 | 1.2 x 1012 | 1.0 x 1012 | 1.3 x 1012 |

| Dielectric constant | 100Hz | 6.15 | 7.07 | 6.99 | 6.56 | 3.89 | |

| Dielectric loss tangent | 100Hz | 0.22 | 0.34 | 0.24 | 0.25 | 0.11 | |

| Grade |   |

|

|

|

|

||

| Capacity | 170g | 170g | 170g | 135ml | |||

| 333ml | 333ml | 333ml | 333ml | 333ml | |||

| Check it at Online-Shop | |||||||

Description of the markexplanation

Super X Gold No.777

Features

- Fast curing

Handling time by the open time about 1 min afterapplication : About 1-2 min./23°C

Handling time by the open time about 2 min afterapplication : About 30 sec.-1 min./23°C

Good low-temperature curing

- Environmental countermeasure products

Avoidance of 14 substances formulated based on the guidelines of the Ministry of Health, Labour and Welfare

Avoidance of poisonous and deleterious substances

Voluntary registration of products not subject to formaldehyde by the Japan Adhesive Industry Association [Conformity to JAIA F☆☆☆☆・4VOCStandards]

Rohs Compliant products

- High durability

Excellent thermal shock resistance and high durability

Application

- For adhesive applications that require initial adhesive strength

- For bonding applications where durability is required by repeated heating, cooling and vibration

Property

| Super X Gold No.777 | |||||

|---|---|---|---|---|---|

| White | Black | Clear | |||

| Application / Properties / Features | High-Speed curing type | ||||

| Type | One component type Elastic Adhesive | ||||

| Base | Special polymer containing silyl group | ||||

| Appearance | White-Whitish Yellow paste (Curing: White) |

Black Paste(Curing: Black) | Light yellow clear paste (Curing: Light yellow) |

||

| Viscosity | Pa・s/23°C | 82.0 | 82.6 | 76.0 | |

| Specific gravity | g/cm3 | 1.14 | 1.14 | 1.02 | |

| Skin over time | 23°C | 2.5 min. | 2.5 min. | 3.5 min. | |

| Adhesive property | Tensile shear strength | MPa | 3.2 | 3.2 | 5.9 |

| T peel strength | N/mm | 3.31 | 3.31 | 3.08 | |

| Curing properties | Hardness | Shore A | 58 | 58 | 60 |

| Breaking strength | MPa | 3.42 | 3.42 | 3.65 | |

| Elongation at break | % | 120 | 120 | 110 | |

| Electrical characteristics | Volume |

Ω・cm | 3.5 x 1012 | 3.5 x 1012 | 2.3 x 1012 |

| Dielectric constant | 100Hz | 5.12 | 6.30 | 3.87 | |

| Dielectric loss tangent | 100Hz | 0.19 | 0.28 | 0.07 | |

| Grade |   |

|

|

||

| Capacity | 135mL | 135mL | 135mL | ||

| Check it at online-shop | |||||

Description of the

Flame-retardant elastic adhesive for electronic devices SX720 Series

Features

- Nonflammable product (UL94V-O listed). (file No.E178790)

- One-part elastic adhesive capable of curing at room temperature and humidity.

- Quick initial adhesion, high tack power for various types of materials, and excellent durability.

- Safe and global environment-friendly adhesive.

Employs no halogen-based, antimony oxide, or phosphorus-based materials.

Designated 14 chemical substances under the guideline of the Ministry of Health, Labour and Welfare are not used.

- Siloxane-free

There is not including low molecular weight cyclosiloxane.

*D3 to D10 Cyclosiloxane compound

Application

- Fixing of circuit boards such as condenser and coil

- Sealing of power supply and transformer for insulation

- Sealing of electronic components for waterproofing

Property

| SX720 Series | ||||||

|---|---|---|---|---|---|---|

| SX720W | SX720WH | SX720B | SX720BH | |||

| Application / Properties / Features | For Electronic devices・UL94 V-0 Certified | |||||

| Type | One component type Elastic adhesive | |||||

| Base | Special polymer containing silyl group | |||||

| Appearance | White Paste | Black P |

||||

| Viscosity | Pa・s/23°C | 42 | 82 | 42 | 82 | |

| Specific gravity | g/cm3 | 1.59 | 1.58 | 1.59 | 1.58 | |

| Skin over time | 23°C | 9min | 7min | 9min | 7min | |

| Adhesive property | Tensile shear strength | MPa | 4.0 | 3.1 | 4.0 | 3.1 |

| T peel strength | N/mm | 0.9 | 1.1 | 0.9 | 1.1 | |

| Curing properties | Hardness | Shore A | 78 | 78 | 78 | 78 |

| Glass transfer point | °C | -60 | -62 | -60 | -62 | |

| Breaking strength | MPa | 3.8 | 3.6 | 3.8 | 3.6 | |

| Elongation at break | % | 40 | 40 | 40 | 40 | |

| Electric Characteristics | Volume |

Ω・cm | 3.0 x 1012 | 2.0 x 1012 | 1.5 x 1012 | 1.6 x 1012 |

| Dielectric constant | 100Hz | 6.3 | 6.0 | 7.0 | 6.2 | |

| Dielectric loss tangent | 100Hz | 0.4 | 0.3 | 0.4 | 0.3 | |

| Grade |  |

|

|

|

||

| Capacity standards | 200g | 200g | 200g | 200g | ||

| 333ml | 333ml | 333ml | 333ml | |||

| Check it at online-shop | ||||||

Description of the

Check it at Online-Shop

※ The link destination is an external site.

※ The link will be broken due to the circumstances of the link seller.

Description of the mark

-

This mark means that products comply with RoHS Directiverequirements.

-

This mark means that products comply with Japanese formaldehyde emission standards for adhesives. These are set forth by the Japanese Industrial Standards (JIS) or Japan Adhesive Industry Association (JAIA).

-

This mark means that products comply with Japanese Voluntary VOC Regulating Rule for Indoor Air Pollution Control. These are set forth by Japan Adhesive Industry Association (JAIA).

-

This mark is a self-management mark for people and environmentally friendly products. We provide products that address environmental and health concerns, mainly for construction and housing applications.