Epoxy Resin AdhesiveEpoxy/silyl terminated polyether elastic adhesive

Features

- This two-part reactive mixture—an epoxy/silyl terminated polyether elastic adhesive—offers a flexible and resilient property that, in clear contrast to the hard and brittle characteristic of conventional epoxy resin adhesives, achieves a major transformation into an adhesive that will not peel off.

- For bonding that requires a high peel resistance and a high shear adhesive strength.

- For bonding in vibrating locations.

- For bonding in an environment subject to large stress variations.

- For bonding different types of materials with substantially different linear expansion coefficients.

- For bonding various types of engineering plastics.

Application

- Applications that require elastic adhesion

1. Bonding of different types of materials with substantially different linear expansion coefficients.

2. Bonding in vibrating locations and in environments subject to large stress variations.

3. Bonding in locations with a large internal strain caused by environmental changes such as thermal cycles. - Applications that require a high peel resistance and a high shear adhesive strength

- Bonding of engineering plastics including commodity plastics

1. Casting and bonding of electrical and electronic parts.

2. Bonding of glass used in precision equipment and optical equipment.

3. Bonding of building components.

4. Bonding of craft products.

Product data

Adhesive properties for various types of adherends

(MPa)| Tensile shear strength | Failure Modes | ||

|---|---|---|---|

| Plastic | PVC | 5.51 | CF |

| PC | 5.46 | CF | |

| ABS | 5.38 | CF | |

| PMMA | 3.72 | CF2AF8 | |

| 6Ny | 4.07 | CF8AF2 | |

| PET | 4.88 | MF | |

| PBT | 3.44 | AF | |

| PPO | 4.16 | CF5AF5 | |

| PPS | 4.19 | CF5AF5 | |

| Metal | SPCC | 6.15 | CF |

| AL | 7.57 | CF7AF3 | |

| SUS | 5.90 | CF8AF2 | |

*CF:Cohesion Failure, AF:Adhesive Failure, TCF:Thin layer cohesion failure, MF:Failure Modes

The numbers indicate their proportion to the adhesion area.

Test method : JIS K6850

Curing: 23°C50%RH×7 days

Characteristics by mixing ratio

| Mixing ratio (Base resin : Hardener) |

Tensile shear strength | Peeling strength | Hardness (Shore A) |

||

|---|---|---|---|---|---|

| Adhesion strength | Failure Modes | Adhesion strength | Failure Modes | ||

| 60 : 40 | 6.04 MPa | CF | 2.90 N/mm | CF | 75 |

| 55 : 45 | 6.15 MPa | CF | 3.14 N/mm | CF | 72 |

| 50 : 50 | 6.15 MPa | CF | 3.85 N/mm | CF | 72 |

| 45 : 55 | 7.10 MPa | CF | 4.12 N/mm | CF | 71 |

| 40 : 60 | 6.09 MPa | CF | 3.90 N/mm | CF | 69 |

*CF:Cohesion Failure

Test method: JIS K6850

Adherends: Steel plate

Surface treatment: Degreased with MEK

Curing: 23°C50%RH×7 days

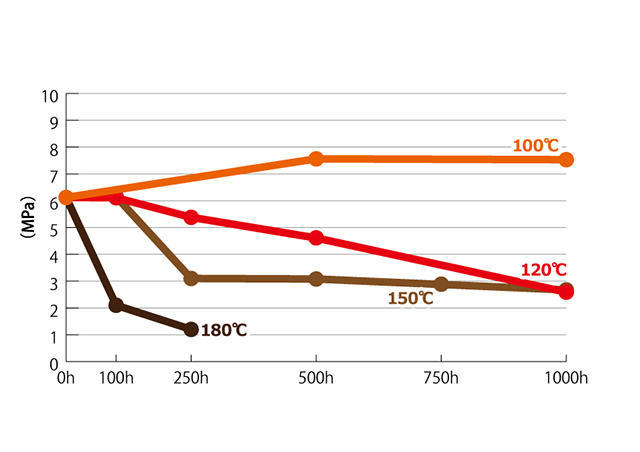

Heat aging test

| Test conditions (temperature×time) |

Tensile shear strength | ||

|---|---|---|---|

| Initial value | 6.15 | CF | |

| 100°C | 500h | 7.56 | CF |

| 1000h | 7.53 | CF | |

| 120°C | 100h | 6.11 | CF |

| 250h | 5.38 | CF | |

| 500h | 4.61 | CF | |

| 1000h | 2.59 | CF | |

| 150°C | 100h | 6.15 | CF |

| 250h | 3.10 | CF | |

| 500h | 3.08 | CF | |

| 1000h | 2.68 | CF | |

| 180°C | 100h | 2.10 | CF |

| 250h | 1.20 | AF | |

*CF:Cohesion Failure,AF:Adhesive Failure

Test method : JIS K6850

Adherends: Steel plate

Surface treatment: Degreased with MEK

Tension speed: 50 mm/min

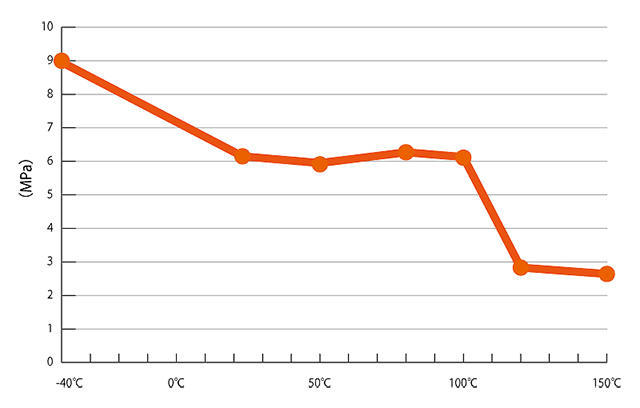

Tensile shear strength on each temp

| Adhesion strength | Failure Modes | |

|---|---|---|

| -40°C | 8.96 | CF |

| 23°C | 6.15 | CF |

| 50°C | 5.95 | CF |

| 80°C | 6.27 | CF |

| 100°C | 6.13 | CF |

| 120°C | 2.83 | CF3AF7 |

| 150°C | 2.64 | CF2AF8 |

*CF:Cohesion Failure

Test method : JIS K6850

Adherends: Steel plate

Surface treatment: Degreased with MEK

Tension speed: 50 mm/min

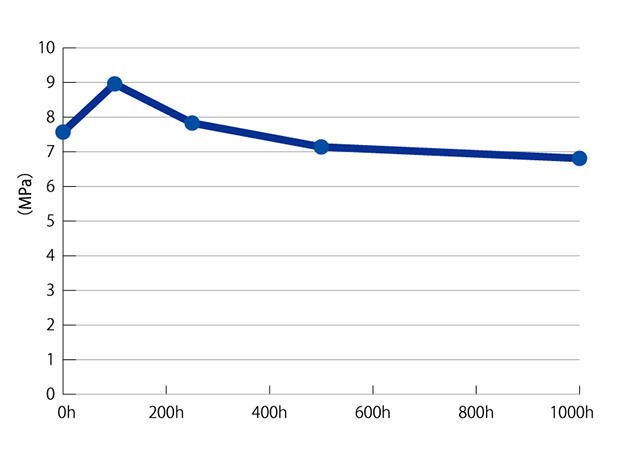

High-temperature and high-humidity test

| Adhesion strength | Failure Modes | ||

|---|---|---|---|

| Initial value | 7.57 | CF | |

| 85°C85% | 100h | 8.96 | CF |

| 250h | 7.83 | CF | |

| 500h | 7.14 | CF | |

| 1000h | 6.81 | CF | |

*CF:Cohesion Failure

Test method : JIS K6850

Adherends: Aluminum

Property

| EP001K | ||||

|---|---|---|---|---|

| Base resin | Hardener | |||

| Application / Properties / Features | Elasticity | |||

| Type | Two-part epoxy adhesive curing at room temperature | |||

| Base | Epoxy resin | Silyl terminated polyether | ||

| Appearance | Milky white | Light yellow | ||

| Non-volatiles | wt% | 99 | 97 | |

| Viscosity | Pa・s/23°C | 14 | 18 | |

| Density | g/cm3 | 1.15 | 1.00 | |

| Standard curing conditions | 23°C×7days | |||

| 23°C 3days+50°C 3days | ||||

| Mixing ratio | 1 : 1 | |||

| Pot life | 23°C | 11分 | ||

| Set time | 23°C | 40 min. | ||

| 23°C | 24 hours | |||

| Cured properties | Hardness | Shore A | 72 | |

| Glass transition temperature | °C | -65 | ||

| Elastic modulus | MPa | 3.2 | ||

| Breaking strength | MPa | 6.7 | ||

| Elongation at break | % | 200 | ||

| Water absorption ratio | % | 1.8 | ||

| Linear expansion coefficient | 15×10-5 | |||

| Capacity | 320ml set | |||

| 2kg set | ||||

| Check it at online-shop | ||||

Check it at Online-Shop

※ The link destination is an external site.

※ The link will be broken due to the circumstances of the link seller.

Description of the mark

-

This mark means that products comply with RoHS Directiverequirements.

-

This mark means that products comply with Japanese formaldehyde emission standards for adhesives. These are set forth by the Japanese Industrial Standards (JIS) or Japan Adhesive Industry Association (JAIA).

-

This mark means that products comply with Japanese Voluntary VOC Regulating Rule for Indoor Air Pollution Control. These are set forth by Japan Adhesive Industry Association (JAIA).

-

This mark is a self-management mark for people and environmentally friendly products. We provide products that address environmental and health concerns, mainly for construction and housing applications.