Double-sided release adhesiveCEMEDINE BBX100

Features

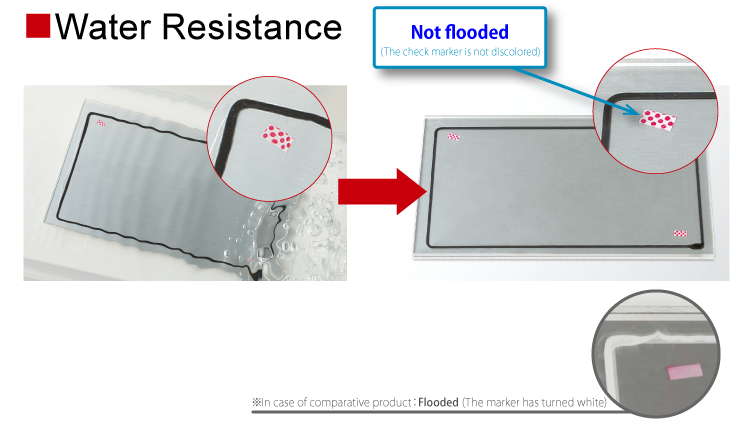

- The adhesive has superior water resistance, which corresponds to IPX8.

- Because it is liquid, the adhesive can be used for thin and uneven substrates and can be used for design alterations.

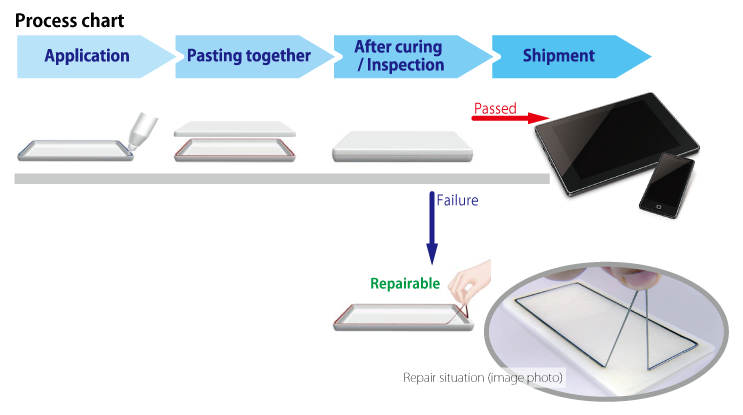

- The adhesive can be used just after being applied. Moreover, because the adhesive secures rework time, it is possible to rework in a plant.

Dispensing / Repair process

Water resistance

Process comparison

| Liquid / moisture curing | Molding | Molding | Liquid / UV curing | Liquid / moisture curing | |||

|---|---|---|---|---|---|---|---|

| BBX100 | Double sided tape | Standard gasket | CIPG | FIPG | |||

| Repairability | Excellent | Good | Excellent | Good *2 | Bad | ||

| Waterproof | Excellent | Good *1 | Good | Excellent | Excellent | ||

| Impact resistance | Excellent | Good | Excellent | Excellent | Excellent | ||

| Design freedom | Excellent | Bad | Bad | Excellent | Excellent | ||

| Workability | Excellent | Good | Bad | Bad | Excellent | ||

| Process time | Excellent | Bad | Bad | Excellent | Excellent | ||

| Cost | Excellent | Bad | Bad | Bad | Excellent | ||

*1 Difficult when it is thin

*2 One side repair

Product data

Adhesive properties for various types of adherends

| Adherends | Tensile shear strength |

Peel strength |

||||

|---|---|---|---|---|---|---|

| Adhesive strength (MPa) |

Material Failure | Adhesive strength (N/25mm) |

Material Failure | |||

| PC | 0.85 | AF | 7.55 | AF | ||

| ABS | 0.87 | CF2AF8 | 10.25 | CF2AF8 | ||

| PMMA | 0.71 | AF | 9.81 | AF | ||

| PA MXD6 | 0.80 | AF | 7.55 | AF | ||

| AL | 1.00 | AF | 8.68 | AF | ||

| Glass | 0.94 | AF | 4.90 | AF | ||

* CF: Cohesion Failure, AF: Adhesive Failure. The figures above show the percentage.

Curing behavior of tensile shear strength

| Tensile shear strength | BBX100 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 day | 3 day | 1 week | 2 week | 4 week | 8 week | ||||||||

| PC | 23°C | 0.56 | AF | 0.67 | AF | 0.85 | AF | 1.19 | AF | 2.91 | AF | 2.86 | AF |

| 30°C | 0.80 | AF | 0.88 | AF | 1.46 | AF | 4.19 | CF2AF8 | 4.31 | CF3AF7 | 4.77 | CF3AF7 | |

| 40°C | 1.64 | CF1AF9 | 1.60 | CF1AF9 | 4.53 | CF | 4.93 | CF | 5.00 | CF | 4.90 | CF | |

| 50°C | 2.20 | CF5AF5 | 2.20 | CF5AF5 | 3.90 | CF8AF2 | 5.83 | CF | 6.10 | CF | 7.19 | CF | |

| ABS | 23°C | 1.12 | AF | 0.99 | CF1AF9 | 0.87 | CF2AF8 | 2.70 | CF1AF9 | 4.48 | CF2AF8 | 5.63 | CF5AF5 |

| 30°C | 1.00 | AF | 1.16 | CF2AF8 | 2.54 | CF2AF8 | 4.26 | CF2AF8 | 6.24 | CF9AF1 | 7.10 | CF | |

| 40°C | 2.16 | CF3AF7 | 2.20 | CF3AF7 | 3.15 | CF4AF6 | 6.14 | CF | 6.17 | CF4AF6 | 7.00 | CF5AF5 | |

| 50°C | 2.70 | CF3AF7 | 3.00 | CF3AF7 | 3.90 | CF5AF5 | 6.12 | CF5AF5 | 6.70 | CF5AF5 | 7.10 | CF6AF4 | |

| PMMA | 23°C | 0.58 | AF | 0.77 | AF | 0.71 | AF | 1.00 | AF | 2.04 | AF | 2.82 | AF |

| 30°C | 0.87 | AF | 0.88 | AF | 1.85 | AF | 3.43 | AF | 3.91 | AF | 4.20 | AF | |

| 40°C | 0.97 | AF | 0.99 | AF | 1.80 | AF | 4.03 | AF | 4.50 | AF | 5.20 | CF2AF8 | |

| 50°C | 0.66 | AF | 1.30 | AF | 2.52 | CF1AF9 | 5.32 | CF2AF8 | 5.80 | CF2AF8 | 6.50 | CF3AF7 | |

| PA MXD6 | 23°C | 0.56 | AF | 0.61 | AF | 0.80 | AF | 1.12 | AF | 2.31 | AF | 3.09 | AF |

| 30°C | 0.60 | AF | 0.71 | AF | 1.20 | AF | 2.00 | AF | 2.30 | AF | 4.12 | AF | |

| 40°C | 0.47 | AF | 0.74 | AF | 1.60 | AF | 2.30 | AF | 2.40 | AF | 3.78 | AF | |

| 50°C | 0.73 | AF | 0.69 | AF | 2.27 | AF | 2.60 | AF | 2.80 | AF | 4.10 | AF | |

| AL | 23°C | 0.58 | AF | 0.85 | AF | 1.00 | AF | 1.22 | AF | 2.25 | AF | 3.28 | AF |

| 30°C | 0.58 | AF | 0.83 | AF | 1.32 | AF | 2.21 | AF | 4.61 | AF | 4.90 | AF | |

| 40°C | 0.58 | AF | 0.79 | AF | 3.08 | AF | 4.42 | CF2AF8 | 5.00 | CF4AF6 | 5.20 | CF4AF6 | |

| 50°C | 0.59 | AF | 0.93 | AF | 2.47 | AF | 4.93 | CF | 5.80 | CF6AF4 | 5.50 | CF5AF5 | |

| GLASS | 23°C | 0.50 | AF | 0.70 | AF | 0.94 | AF | 1.49 | AF | 2.53 | AF | 3.51 | AF |

| 30°C | 0.36 | AF | 1.00 | AF | 1.31 | AF | 2.20 | AF | 3.08 | AF | 4.08 | AF | |

| 40°C | 0.77 | AF | 1.00 | AF | 1.20 | AF | 2.49 | AF | 3.07 | AF | 3.91 | AF | |

| 50°C | 0.82 | AF | 1.50 | AF | 1.90 | AF | 2.28 | AF | 3.50 | AF | 4.21 | AF | |

CF: Cohesion Failure, AF: Adhesive Failure. The figures above show the percentage.

Compliant with JIS K6850Coating quantity : Coated on both sides 100μm thick (per side)

Open time : 2 min

Pressing : 2 pinches

Curing: 23°C50%RH x 7 days

Application area : 25mm×25mm

Tension speed : 50 mm/min

Destruction State : Confirmation by seeing

Curing behavior of peel strength

| Peel strength | BBX100 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 day | 3 day | 1 week | 2 week | 4 week | 8 week | ||||||||

| PC | 23°C | 6.96 | AF | 7.35 | AF | 7.55 | AF | 9.41 | AF | 9.81 | AF | 9.95 | AF |

| 30°C | 7.11 | AF | 8.63 | AF | 9.81 | AF | 10.79 | AF | 11.87 | AF | 13.04 | AF | |

| 40°C | 7.70 | AF | 8.34 | AF | 11.72 | CF1AF9 | 15.20 | CF2AF8 | 14.22 | CF3AF7 | 15.30 | CF3AF7 | |

| 50°C | 8.58 | AF | 9.46 | AF | 12.90 | CF3AF7 | 13.58 | CF5AF5 | 14.22 | CF5AF5 | 17.16 | CF6AF4 | |

| ABS | 23°C | 8.14 | AF | 9.66 | CF1AF9 | 10.25 | CF2AF8 | 11.52 | CF5AF9 | 12.45 | CF6AF4 | 13.24 | CF5AF5 |

| 30°C | 7.55 | AF | 11.33 | CF5AF5 | 13.09 | CF6AF4 | 15.74 | CF9AF1 | 15.64 | CF7AF3 | 17.36 | CF7AF3 | |

| 40°C | 7.94 | CF1AF9 | 10.84 | CF2AF8 | 11.82 | CF5AF5 | 15.98 | CF9AF1 | 16.08 | CF9AF1 | 18.19 | CF8AF2 | |

| 50°C | 8.92 | CF2AF8 | 13.73 | CF2AF8 | 13.44 | CF5AF5 | 17.65 | CF | 19.61 | CF | 22.31 | CF | |

| PMMA | 23°C | 7.35 | AF | 7.55 | AF | 9.81 | AF | 11.47 | AF | 12.65 | AF | 13.14 | AF |

| 30°C | 8.09 | AF | 8.63 | AF | 12.26 | AF | 15.20 | AF | 17.60 | CF8AF2 | 19.12 | CF | |

| 40°C | 7.85 | AF | 9.66 | AF | 10.00 | CF1AF9 | 15.00 | CF3AF7 | 14.22 | CF3AF7 | 15.49 | CF3AF7 | |

| 50°C | 8.48 | AF | 12.70 | CF1AF9 | 13.83 | CF5AF5 | 18.00 | CF | 17.65 | CF | 17.75 | CF | |

| PA MXD6 | 23°C | 5.00 | AF | 5.93 | AF | 7.55 | AF | 9.27 | AF | 10.79 | AF | 12.65 | AF |

| 30°C | 5.64 | AF | 6.91 | AF | 8.04 | AF | 12.01 | AF | 12.85 | AF | 14.71 | AF | |

| 40°C | 5.74 | AF | 7.26 | AF | 8.19 | AF | 10.10 | AF | 12.31 | AF | 14.76 | AF | |

| 50°C | 6.57 | AF | 6.77 | AF | 11.77 | AF | 12.65 | AF | 12.85 | AF | 14.32 | AF | |

| AL | 23°C | 5.39 | AF | 8.34 | AF | 8.68 | AF | 10.59 | AF | 11.96 | AF | 15.74 | AF |

| 30°C | 5.64 | AF | 8.14 | AF | 9.66 | AF | 12.26 | AF | 14.71 | AF | 16.77 | AF | |

| 40°C | 5.00 | AF | 7.75 | AF | 8.04 | AF | 8.97 | AF | 15.30 | AF | 18.83 | AF | |

| 50°C | 4.51 | AF | 9.12 | AF | 9.46 | AF | 10.89 | AF | 13.78 | AF | 20.01 | AF | |

| GLASS | 23°C | 3.19 | AF | 4.90 | AF | 7.89 | CF3AF7 | 9.51 | CF4AF6 | 11.82 | CF | ||

| 30°C | 2.55 | AF | 5.39 | AF | 9.07 | CF | 9.81 | CF | 12.65 | CF | |||

| 40°C | 4.36 | AF | 5.20 | AF | 8.09 | CF8AF2 | 8.97 | CF | 18.04 | CF | |||

| 50°C | 6.03 | AF | 5.25 | AF | 8.83 | CF | 11.33 | CF8AF2 | 22.85 | CF5AF | |||

CF: Cohesion Failure, AF: Adhesive Failure. The figures above show the percentage.

Compliant with JIS K6854-2

Substrate : Various materials x Canvas

Coating quantity : Coated on both sides 300μm thick (per side)

Pressing : Rubber roller

Tension speed : 200 mm/min

Destruction State : Confirmation by seeing

Durability / High-temperature and high-humidity

| Durability : high-temperature and high-humidity | PC | ABS | SPCC | |||||

|---|---|---|---|---|---|---|---|---|

| Test conditions | Adhesive strength | Material Failure | Adhesive strength | Material Failure | Adhesive strength | Material Failure | ||

| Tensile shear strength (MPa) | 23°C50%RH | 7week | 0.85 | AF | 0.87 | AF | 0.40 | AF |

| 85°C85%RH | 500h | 0.18 | AF | 1.79 | CF | 1.85 | CF2AF8 | |

| 1000h | 0.11 | AF | 1.77 | CF | 1.99 | CF2AF8 | ||

| 2000h | 0.22 | AF | 1.76 | CF | 1.65 | CF2AF8 | ||

| Peel strength (N/25mm) | 23°C50%RH | 7week | 7.55 | AF | 10.25 | AF | 1.70 | AF |

| 85°C85%RH | 500h | 30.02 | AF | 76.41 | CF7AF3 | 37.17 | AF | |

| 1000h | 28.60 | AF | 56.05 | CF7AF3 | 47.15 | AF | ||

| 2000h | 14.79 | CF1AF9 | 65.06 | CF5AF5 | 56.22 | AF | ||

CF: Cohesion Failure, AF: Adhesive Failure. The figures above show the percentage.

Durability / Heat cycle

| Durability : Heat cycle | PC | ABS | SPCC | |||||

|---|---|---|---|---|---|---|---|---|

| Test conditions | Adhesive strength | Material Failure | Adhesive strength | Material Failure | Adhesive strength | Material Failure | ||

| Tensile shear strength (MPa) | 23°C50%RH | 7 day | 0.85 | AF | 0.87 | AF | 0.40 | AF |

| -40°C×30min ↑↓ 80°C30min |

500h | 0.59 | AF | 1.72 | CF8AF2 | 0.81 | AF | |

| 1000h | 0.69 | AF | 1.70 | CF7AF3 | 0.75 | AF | ||

| 2000h | 0.48 | CF1AF9 | 1.52 | CF3AF7 | 1.25 | AF | ||

| Peel strength (N/25mm) | 23°C50%RH | 7 day | 7.55 | AF | 10.25 | AF | 1.70 | AF |

| -40°C×30min ↑↓ 80°C×30min |

500h | 81.73 | CF7AF3 | 78.40 | CF7AF3 | 7.18 | AF | |

| 1000h | 79.45 | CF | 83.19 | CF6AF4 | 6.41 | AF | ||

| 2000h | 84.66 | CF1AF9 | 88.40 | CF4AF6 | 13.55 | AF | ||

CF: Cohesion Failure, AF: Adhesive Failure. The figures above show the percentage.

Property

| BBX100 | |||

|---|---|---|---|

| Application / Properties / Features | Repairable seal material | ||

| Type | One-part moisture curable elastic adhesive | ||

| Base | Acrylic modified silicone resin | ||

| External appearance | Black paste | ||

| Viscosity | Pa・s/23°C | 300 | |

| Specific gravity | g/cm3 | 1.18 | |

| Skin over time | 23°C | 35 min | |

| Curing properties | Hardness | Shore A | 35 |

| Breaking strength | MPa | 0.29 | |

| Elongation at break | % | 200 | |

| Capacity standards | 330mL | ||

Appearance: Confirmation by seeing

Viscosity: BS-type rotational viscometer (Rotor No.7, 10 rpm)

SVI: Viscosity ratio between 10 rpm and 1 rpm

Density: Based on the specific gravity cup method in JIS K6833 6.1.1

Dumbbell test: Dumbbell No.3 ( thickness : 1.2 mm)

Check it at Online-Shop

※ The link destination is an external site.

※ The link will be broken due to the circumstances of the link seller.

Description of the mark

-

This mark means that products comply with RoHS Directiverequirements.

-

This mark means that products comply with Japanese formaldehyde emission standards for adhesives. These are set forth by the Japanese Industrial Standards (JIS) or Japan Adhesive Industry Association (JAIA).

-

This mark means that products comply with Japanese Voluntary VOC Regulating Rule for Indoor Air Pollution Control. These are set forth by Japan Adhesive Industry Association (JAIA).

-

This mark is a self-management mark for people and environmentally friendly products. We provide products that address environmental and health concerns, mainly for construction and housing applications.