Welding Process / Painting Process / ComponentsAutomobiles Adhesive

Automobiles Adhesive

Technologies which connect Automotive Future and the World. Aiming to become a company which is essential for the automobile industry with global expansion.

For inquiries, please feel free to contact us.

Automotive Sales & Marketing Department

TEL +81-3-6421-7407

FAX +81-3-6421-7409

*Click here for inquiries regarding other adhesives other than for automotive use. Click here

Product lineup

Welding Process|Features

Mastic Adhesive

- Synthetic rubber - based rubbery elastic product with low distortion Performance.

- Dischargeable with airless pump of over 45:1 compression ratio in room temperature.

- Good shower resistance, adhesiveness to oil surface, durability.

Spot Sealer

- Synthetic resin- based Rubbery elastic product.

- Application to welding parts enables good waterproof and dustproof performance.

- Discharging in room temperature is possible with airless pump of compression ratio over 45:1.

- Good shower resistance, Oil surface adhesiveness, and High durability

Hemming Adhesive

- Solventless ONE-PART HEAT CURING TYPE structural epoxy adhesive which is excellent in durability.

- Uniform particle size glass bubbles enable good performance on temporary tacking.

- Excellent adhesiveness for Oil surface steel plate, Alloying Hot-dip galvanized steel plates.

- ED paintabiliy enables excellent rustproof performance.

Hemming Adhesive

- Solventless ONE-PART HEAT CURING TYPE structural epoxy adhesive which is excellent in durability.

- Uniform particle size glass bubbles enable good performance on temporary tacking.

- Excellent adhesiveness for Oil surface steel plate, Alloying Hot-dip galvanized steel plates.

- ED paintabiliy enables excellent rustproof performance.

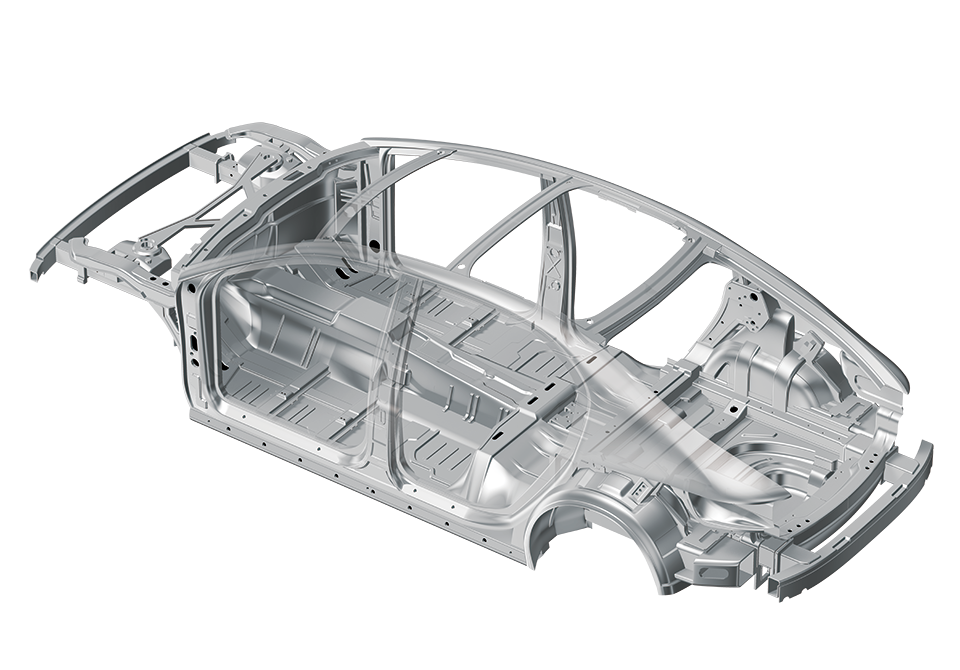

Structural Adhesive

- Solventless ONE-PART HEAT CURING TYPE structural epoxy adhesive is excellent in durability.

- Excellent adhesiveness for oil surface steel plate, galvannealed steel plates.

- Using with spot welding to automotive flames, body rigidity is improved.

- This item has strong adhesiveness and shock resistance.

- High viscosity type with excellent in shower resistance can be also offered.

Data

| Welding Process | |||||

|---|---|---|---|---|---|

| Mastic Adhesive | Spot Sealer | Hemming Adhesive | Structural Adhesive | ||

| Application | Hood/Bonne | Wheel House in section | Door | The vehicle body frame | |

| Features | Solventless type | Solventless type | Solventless type | Solventless type | |

| Heat Curing | Thermosetting | Dischargeable in Room Temperature | Dischargeable in Room Temperature ONE-PART HEAT CURING TYPE | ||

| Filling Adhesive | Filling Adhesive | One-Component Thermosetting Adhesive for Oil Surface | Oil surface Adhesive | ||

| Dichargeable with Pump in Room Temperature | Pump Dischargeable in Room Temperature | ||||

| Good shower resistance | Good shower resistance | ||||

| Main Composition | Synthetic rubber | Synthetic resin | Epoxy resin | Epoxy resin | |

| Appearance | High viscosity uniform paste | High viscosity uniform paste | High viscosity uniform paste | High viscosity uniform paste | |

| Viscosity | 200~400 Pa・s | 200~400 Pa・s | 200~300 Pa・s | 200~300 Pa・s | |

| Density | g/cm3 | 1.3~1.5 | 1.3~1.5 | 1.3~1.5 | 1.2~1.4 |

| Solids content | 95%≤ | 98%≤ | 98%≤ | 98%≤ | |

| Peel strength | 200~1000 kPa | 100~300 kPa | 15~20 kPa | 15~20 kPa | |

| Hardness | 10~40 HSA | ||||

Painting Process|Features

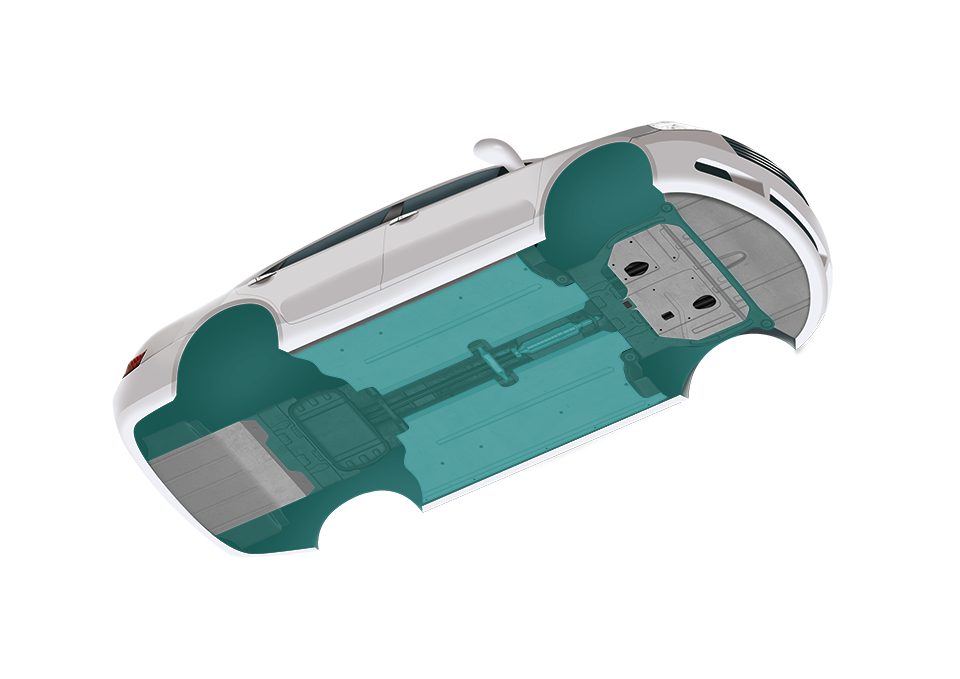

Under Body Coating (UBC)

- Acryl Sol or PVC Sol- based plastisol coating to automotive underfloor and rustproof chip for wheelhouse.

- Spray Application with airless spray is possible.

- Various UBS aimed for Soundproof, Thin film weight reduction and High physical property for thin film can be offered.

Coating Type Damping Material

- ACRYLIC EMULSION-based Coating Material aimed for vibration reduction of vehicle body.

- Application with airless bump is possible.

- Baking hardenable type (Recommended baking temp.:120-160°C)

- Baking hardening creates forming foamed film and excellent dumping performance.

- Sprayable melt sheet

- Sound deadening (Reduce sound level)

- Vibration reduction

- Weight reduction

- Easy vertical application

- Space save

- Improve the paint quality

Body Sealer

- PVC Sol - based water stop and rustproof plastisol coating for outside and inside panel of automobile.

- Spray application with airless spraying is possible.

- In addition to standard type, low VOC type can be offered.

Interlayer Resistance Chip

- PVC Sol - based plastisol coating for automotive anti-chipping.

- Spray Application with airless spray is possible.

- Low viscosity enables excellent spray performance.

- By thinly coating on rocker parts (SIDE SILL), excellent membrane property is contributed.

Data

| Painting Process | |||||

|---|---|---|---|---|---|

| Under Body Coating (UBC) | Coating Type Damping Material | Body Sealer | Interlayer Resistance Chip | ||

| Usage | Wheelhouse, Under floor | Floor | Interior, Exterior | Rocker | |

| Features | Airless Spray |

Aqueous coating type damping material |

Airless Spray | Airless Spray | |

| Added Various Functions | Thermosetting-type | Added Various Functions | Added Various Functions | ||

| Main Composition | PVC or Acryl resin | Acrylic emulsion | PVC resin | PVC resin | |

| Appearance | High viscosity uniform Paste | Gray colored Uniform Paste | High viscosity uniform paste | Low Viscosity Uniform Paste | |

| Viscosity | 60~120 Pa・s | 80~120 Pa・s | 60~120 Pa・s | 5~20 Pa・s | |

| Density | g/cm3 | 1.3~1.4 | 1.5~1.6 | 1.4~1.6 | 1.3~1.4 |

| Solids content | 95%≤ | 80%≤ | 98%≤ | 90%≤ | |

| Peel strength | 0.3~2 MPa | 0.6~2.0 MPa | 1.0~2.0 MPa | ||

| Hardness | 50~70 | 60~80 | 50~70 | ||

| Expansion rate | 1.6~1.8 times | ||||

Components|Features

Interior Parts Adhesive

- Good spray-usability with uniform adhesiveness to wide surface.

- Adhesive for Automobile Interior Trim which enables spray coating with efficient operation for wide surface.

- Satisfy the regulated standard of volatile organic compounds (VOCs) for vehicle compartment.

- Good adhesiveness to highly-recyclable PP resin, various types of surface skin for automobile interiors, fabric, PP foam, urethane foam, and various types of skin materials such as leather. (Chloroprene Type)

- Good adhesiveness to steel plate, ABS, Vinyl chloride, Vinyl chloride foam. (Urethane Type)

- High Spraying Usability with uniform application enables low press pressure operation in low temperature and short-time dry condition.

- Good endurance ( wet and heat resistance) enables good performance under severe environment.

Adhesive for Brakes

- Solvent type One-Component Thermosetting, Phenol Adhesive with excellent in heat resistance.

- Good heat resistance of this product is appropriate for adhering brake linings of automobiles and motorcycles, and clutch facings.

- To improve resistance for shock, bending, and detachment, we have mixed adhesive grade of thermosetting resin and synthetic rubber with;

- Strong adhesiveness at high temperature excelling in heat aging resistance.

- Strong in shock, bending, vibration with durability against repetitive heating and loading, and less deterioration in adhesive force.

- Good flowability and quick in drying.

- Strong resistance to water, oil, solvent, and medical agents.

Data

| Components | ||||

|---|---|---|---|---|

| Interior Parts Adhesive | Adhesive for Brakes | |||

| Usage | Door Trim, Baggage Tray, Instrument Panel, Pillar, Trank Cover etc | Drum brake | ||

| Features | Chloroprene Adhesive / Urethane Adhesive | One-Component Thermosetting High Heat Resistance Adhesive | ||

| Solvent type | Solvent type | |||

| Spray Type | Dischargeable in Room Temperature | |||

| Main Composition | Chloroprene Type | Urethane Type | Phenol resin | |

| Interior for Vehicles | Interior for Vehicles | |||

| Substrate (Mainly PP) x Skin material | One pot type | |||

| Appearance | Transparent, No-colored, Uniform liquid | Transparent, No-colored, Uniform liquid | Light brown, Black Paste | |

| Viscosity | 150~250 cps | 150~250 cps | 100~20,000 cps | |

| Density | g/cm3 | 0.7~0.9 | 0.9~1.0 | 0.9~1.1 |

| Solids content | 18~25% | 30~40% | 25~55% | |

| Peel strength | 20N/25mm | 9N/25mm | ||

| Creep performance | 180° creep | 180° creep | ||

| Room temperature ·80° 0mm | Room temperature ·80° 0mm | |||

| Appropriate forced dying condition | 180~200°C x 15~30min | |||

For inquiries, please feel free to contact us.

Automotive Sales & Marketing Department

TEL +81-3-6421-7407

FAX +81-3-6421-7409

*Click here for inquiries regarding other adhesives other than for automotive use. Click here

Check it at Online-Shop

※ The link destination is an external site.

※ The link will be broken due to the circumstances of the link seller.

Description of the mark

-

This mark means that products comply with RoHS Directiverequirements.

-

This mark means that products comply with Japanese formaldehyde emission standards for adhesives. These are set forth by the Japanese Industrial Standards (JIS) or Japan Adhesive Industry Association (JAIA).

-

This mark means that products comply with Japanese Voluntary VOC Regulating Rule for Indoor Air Pollution Control. These are set forth by Japan Adhesive Industry Association (JAIA).

-

This mark is a self-management mark for people and environmentally friendly products. We provide products that address environmental and health concerns, mainly for construction and housing applications.